3D-printed mass spectrometer filters: lighter, cheaper and just as precise

Researchers from Massachusetts Institute of Technology (MIT; USA) have successfully 3D printed quadrupole mass filters (QMFs), the key component of mass spectrometers, that are significantly lighter, more cost-effective than filters made using traditional techniques and materials, and offer commercial-grade precision. The filters can be printed in one step and can withstand temperatures up to 900 °C.

Mass spectrometers—devices used to measure mass-to-charge ratios—are widely used by the bioanalytical community for quantitative chemical analysis. However, mainstream mass spectrometers are bulky, expensive and easily damaged, limiting their use in situ.

Using additive manufacturing, researchers at MIT have successfully produced a miniaturized filter that can be assembled in a few hours. Despite costing only a few dollars, the 3D-printed filters demonstrated precision equivalent to some commercial-grade mass filters, which cost > USD $100,000 and take weeks to manufacture. The filter is built from durable and heat-resistant glass-ceramic resin and can be printed in one step, eliminating the need for assembly, which usually introduces defects that impede the performance of the filter.

Luis Fernando Velásquez-García, Principal Research Scientist at MIT’s Microsystems Technology Laboratories, has endured a 20-year journey to produce the 3D-printed, portable mass spectrometer.

“We are not the first ones to try to do this. But we are the first ones who succeeded at doing this. There are other miniaturized quadrupole filters, but they are not comparable with professional-grade mass filters. There are a lot of possibilities for this hardware if the size and cost could be smaller without adversely affecting the performance”, says Velásquez-García.

So why does size matter?

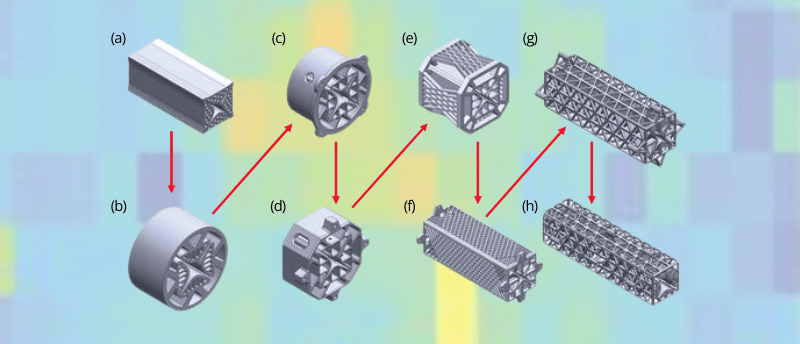

QMFs employ a set of four precisely positioned rods that are biased at a mix of radio frequency and direct current voltages to create a well that only transmits ions of a particular charge-to-mass ratio. Depending on the properties of the electromagnetic field, ions with specific mass-to-charge ratios will move through the middle of the filter, while other particles escape out of the sides. By varying the mix of voltages, ions with different mass-to-charge ratios can be targeted.

Although simple in design, a typical stainless-steel QMF can weigh several kilograms. QMF miniaturization has long been a sought-after goal, but shrinking the filter typically introduces manufacturing errors and compromises sensitivity due to reduced ion collection.

“You can’t make quadrupoles arbitrarily smaller — there is a trade-off,” Velásquez-García adds.

Velásquez-García’s team navigated this trade-off by leveraging additive manufacturing to produce the miniaturized QMFs with an optimal size and shape to maximize precision and sensitivity. The filters were produced using glass-ceramic resin, a relatively new printable material that can withstand temperatures up to 900 °C and performs well in a vacuum.

You may also be interested in:

- Summer studentship opportunities with the Chromatographic Society and British Mass Spectrometry Society 2024

- Middle-down mass spectrometry: an interview with Roxana McCloskey

- Development of a novel hybrid immunoaffinity-liquid chromatography mass spectrometry (IA-LCMS) approach to supplement ADA testing

Maximizing performance

The research team tested the 3D-printed QMFs by swapping them into a commercial system. Their finding revealed that their QMFs, measuring ~12 cm in length and a quarter of the density of comparable stainless-steel filters, could attain higher resolutions than other miniature filters. Further investigation uncovered that the QMFs could achieve precision equal to that of large commercial filters. The team plans to make the filters longer to optimize their performance further, as well as explore different ceramic materials that could better transfer heat in the future.

“Our vision is to make a mass spectrometer where all the key components can be 3D printed, contributing to a device with much less weight and cost without sacrificing performance. There is still a lot of work to do, but this is a great start,” Velásquez-Garcia adds.

Sources: Eckhoff CC, Lubinsky NK, Metzler LJ, Pedder RE and Velásquez-García LF. Low-cost, compact quadrupole mass filters with unity mass resolution via ceramic resin vat photopolymerization. Adv. Sci. dio:202307665 (2023).